Exactly How to Make Certain Durability and Reliability with a High-Quality Membrane Switch

Exactly How to Make Certain Durability and Reliability with a High-Quality Membrane Switch

Blog Article

How Membrane Layer Changes Contribute to the Resilience of Electronic Control Panels

Membrane layer switches play a vital role in boosting the longevity of digital control board, mostly with their multi-layered building which provides effective defense against environmental aspects such as wetness and dirt. This layout not just decreases the risk of circuit damage and rust but likewise advertises ease of upkeep due to its smooth surface. The absence of relocating parts dramatically minimizes the chance of mechanical failings, making membrane layer switches suitable for requiring applications. Nevertheless, the effects of these attributes expand past mere security, increasing inquiries regarding their broader effect on functionality and customer experience.

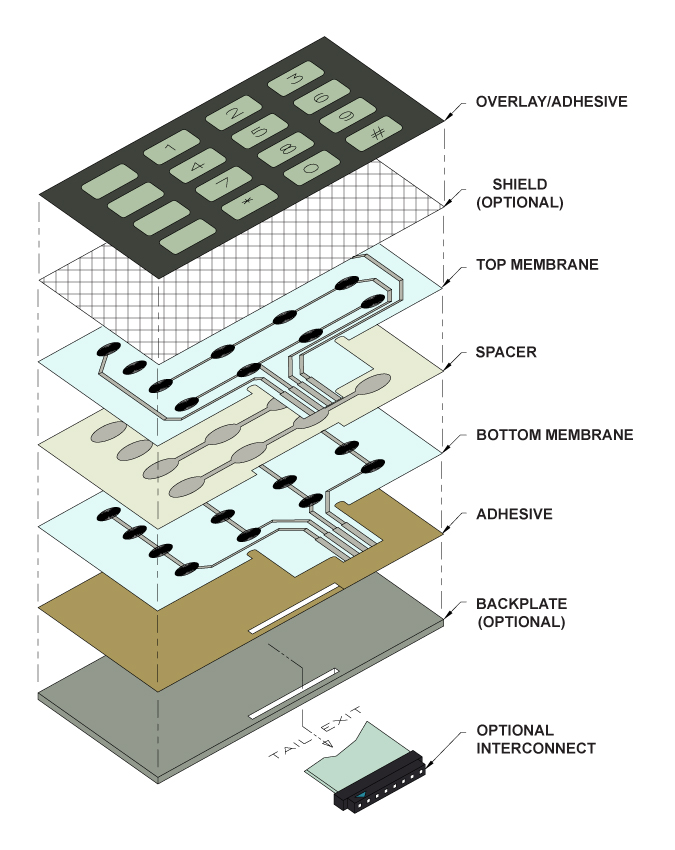

Interpretation of Membrane Buttons

Membrane layer buttons are made to be thin and light-weight, making them appropriate for applications where room is limited. They can be produced in numerous forms, dimensions, and shades, supplying adaptability in style that meets aesthetic and functional needs. Additionally, membrane buttons can incorporate different modern technologies, such as responsive feedback and LED signs, boosting user experience.

Due to their building and construction, membrane buttons are often resistant to dust, wetness, and general wear, adding to their sturdiness popular environments. Their seamless layout not only facilitates easy cleansing yet likewise decreases the risk of mechanical failure, making them a preferred selection for suppliers seeking reputable interface in their digital control board.

Security Against Ecological Factors

The layout of membrane layer changes naturally gives a degree of defense against different environmental aspects, which is crucial for preserving performance in challenging conditions - Membrane Switch. These buttons are commonly built with layers of adaptable products that protect internal components from moisture, dust, and pollutants. By enveloping the wiring, membrane changes lessen the risk of short circuits and corrosion, which can considerably hinder efficiency

Moreover, using robust adhesives and sealants during manufacturing improves their resistance to ecological challenges. Membrane layer buttons can withstand exposure to chemicals and solvents, making them suitable for markets such as food processing and healthcare, where hygiene and sanitation are critical. Their seamless surface area style likewise prevents the accumulation of dirt and germs, facilitating less complicated cleansing and upkeep.

Temperature variations are one more environmental worry, and membrane switches are crafted to operate efficiently throughout a vast array of temperature levels (Membrane Switch). This flexibility makes sure that control board stay functional in numerous setups, from industrial atmospheres to customer electronic devices

Impact on Customer Interaction

Individual communication with digital control panels is significantly influenced by the layout and capability of membrane layer buttons. These buttons offer a tactile user interface that boosts the total user experience, enabling instinctive navigating and control. Their receptive nature makes certain that individuals obtain immediate comments upon activation, which is crucial for jobs requiring precision and efficiency.

In addition, the smooth surface of membrane layer switches over assists in simple cleaning and maintenance, promoting individual confidence in the integrity of the user interface. This tidiness is particularly vital in environments where health is paramount, such as clinical or food processing settings. Additionally, the small and light-weight design of membrane layer switches over adds to the visual charm of control board, motivating individual involvement with a modern and smooth look.

Moreover, the assimilation of aesthetic aspects, such check this as printed symbols and backlighting, assists customers rapidly determine functions, reducing the finding out contour connected with brand-new devices. Because of this, customers can run tools better, bring about raised performance and satisfaction. In summary, membrane buttons play a pivotal role in enhancing individual communication by integrating functionality, aesthetic appeals, and ease of use, eventually resulting in improved operational efficiency.

Layout Adaptability and Customization

Layout adaptability and customization are essential facets of membrane buttons, enabling makers to customize digital control board to particular applications and user demands. This adaptability enables the assimilation of different design elements, such as colors, graphics, and structures, which can our website enhance the visual charm and individual engagement of the control panel.

Membrane switches can be tailored in size and form, accommodating a wide variety of devices and applications, from industrial equipment to consumer electronic devices. This convenience ensures that makers can create user-friendly user interfaces that align with individual expectations and operational needs. Furthermore, the capability to include distinct functions such as backlighting or responsive responses better enhances functionality, enabling a much more interactive experience.

Moreover, the manufacturing process for membrane switches over supports the rapid prototyping of styles, allowing makers to repeat and improve their concepts promptly. This capability not just accelerates the advancement timeline but likewise guarantees that the end product fulfills particular functional and visual standards.

Cost-Effectiveness and Long Life

Cost-effectiveness and long life are considerable benefits of membrane switches, making them an eye-catching option for suppliers and end-users alike. These buttons are typically more economical to generate than conventional mechanical switches, mainly due to their simplified production processes and the reduced variety of parts required. This expense benefit expands not only to preliminary manufacturing yet also to check out this site long-term operational expenses, as membrane layer buttons often need less upkeep and have a lower failing rate.

Furthermore, the longevity of membrane switches adds to their total value. Created from durable products, they are immune to environmental aspects such as wetness, dust, and chemicals, which can bring about early wear in other switch types. The absence of moving parts reduces mechanical failure, allowing membrane layer switches to keep capability over expanded durations.

This resilience is especially advantageous in applications requiring regular performance under demanding conditions, such as medical tools and commercial devices. Ultimately, the mix of cost-effectiveness and long life makes membrane layer switches over an economically sensible choice for makers, giving dependable options that stand up to the examination of time while optimizing budgetary factors to consider.

Conclusion

In final thought, membrane switches significantly enhance the longevity of electronic control panels through their durable building and construction and protective functions - Membrane Switch. Generally, membrane switches over stand for a reliable and cost-effective choice for improving the durability and performance of digital control systems.

Report this page